Hiding within the walls and under the floors of your home, there are many different types of pipes coming and going. Some supply you with clean water, and others take away the waste so you don't have to worry about it. While the difference between water pipes and wastewater pipes is quite clear, the difference between soil pipes and waste pipes can be a bit murkier.

Hiding within the walls and under the floors of your home, there are many different types of pipes coming and going. Some supply you with clean water, and others take away the waste so you don't have to worry about it. While the difference between water pipes and wastewater pipes is quite clear, the difference between soil pipes and waste pipes can be a bit murkier.

Unless you are a qualified plumber or work in the drainage industry, it is likely that you've never needed to know the difference between the two, as both basically just remove the waste from your home and carry it to the sewer, which is all most of us are concerned about. As long as it works, why should we worry? Hopefully, for most of us, the answer is that we shouldn't need to worry at all. We should be able to run our taps, fill our baths, and flush our toilets in blissful ignorance of the dirty work these unsung heroes of the household system have to do. The problem, however, comes when something goes wrong.

Whether by the clog (i.e. excessive use of toilet paper etc.) or the slow decay of time (i.e. wear and tear in older properties), your soil and waste systems will inevitably need some maintenance, repair, or even replacing at some point. It's at these times when knowing your soil pipes from your waste pipes becomes vital.

What is the difference between a Soil Pipe & a Waste Pipe?

While both types of pipe transport wastewater away from your home into the sewer, there are some crucial differences that you need to be aware of. Basically:

- Soil Pipes are designed to transport the soiled water (blackwater) from your toilet, urinal, or bidet (if you're fancy).

- Waste Pipes are designed to transport the wastewater (greywater) from your sinks, shower, bath, washing machine, or dishwasher.

An easy way to remember which way round it works is to think of this rhyme:

But why is it important to make this differentiation? Why can't one pipe service all wastewater needs if they both carry it out to the sewer? Why does it matter whether you use soil pipes or waste pipes? The answer lies in what they are used for and the way they are vented.

Bodily waste produces methane and other unpleasant/dangerous gasses that must be vented out of the system before reaching the sewer. For this reason, soil pipe systems are typically designed to be vented through the roof of your home to allow the gasses to escape out into the air. The wastewater produced by washing your hands, having a shower, washing your clothes, or doing the dishes doesn't produce these gasses however, therefore waste pipe systems don't require this ventilation.

Soil pipes also need to be larger in diameter than waste pipes on the account of having to handle more…solid materials. While having your sink drain into a soil pipe wouldn't really matter much (apart from using up an unnecessary amount of space under it), having your toilet drain into a waste pipe would be a recipe for a very unpleasant disaster in your home.

Making sure the right waste is going down the right drain is vital for the health of your household drainage systems.

Does age matter - what type of system does your property have?

The age of your property can actually cause an extra layer of confusion to this simple explanation of soil and waste systems. Older properties, that haven't had any significant renovations done since they were built, can have two separate systems for soil and waste that combine when they reach the drain before exiting out into the underground sewer. Many newer properties, on the other hand, now make use of a simpler single pipework system. The toilets are still connected to soil pipes, and the sinks and baths etc., are still connected to waste pipes, but they all connect to an internal soil stack. This is a soil pipe that runs vertically through the property carrying all its wastewater down to the drain while also venting out through the roof to release the dangerous gasses.

Older properties that have been heavily renovated or converted may have either of these systems or even a combination of the two. This is often made evident by the use of an external soil stack running up the outside of the building. It is even more imperative in such cases that you ensure you have the right connections for your wastewater. If there is even a hint of doubt, always call in a professional to survey the system before doing any plumbing work.

So, there is a brief overview of the main differences between soil and waste systems. Know your pipes, know your system, or call in a professional; that's the long and short of it. For those looking for a more detailed explanation of both systems, though, keep on reading.

Soil Pipe System Overview

A soil system, as previously mentioned, is made up of pipes and fittings capable of carrying soiled water and solids from your toilets out to the sewer. The pipes used in its construction must be of a large enough diameter to allow solid waste to pass. For this reason, soil pipes are usually sold in either 110mm or 160mm diameters. The 110mm is the most common size, especially for above ground soil systems, with the 160mm size generally used to carry the main flow underground when a number of houses are joined together. Pipes smaller than 110mm should never be used to carry waste from toilets as they will not be designed to handle solid waste and will almost certainly become blocked.

Traditionally, soil pipes were most commonly made from cast iron, and some older properties may still have them. Most modern systems, however, are now built with plastic pipes and fittings. Being more lightweight and flexible, while still being tough and resistant to chemicals, makes plastic drainage pipes an attractive installation option in this day and age. They are typically also available in longer lengths than cast iron pipes too, which means fewer joints need to be made when connecting up a complete system. If your property does have an existing cast iron soil stack, though, we would highly recommend seeking advice from a professional plumber before making any alterations or repairs. Some of the older cast iron systems can still contain asbestos - which isn't something you want to go messing around with unless you absolutely know what you are doing.

Dealing with plastic systems is a lot more straightforward, as most plastic drainage pipes are designed to be compatible with each other regardless of the manufacturer. If they aren't, conversion fittings are usually readily available to make connections as easy as possible. The only caveat to this is that different connection types shouldn't generally be mixed. For soil pipes, the two main connection types are either Ring Seal or Solvent Weld, meaning that if the system you are connecting to is a Solvent Weld system, you should ideally be using Solvent Weld pipes and fittings rather than Ring Seal, and visa-versa. "But what is the difference between these two connection types?" we hear you ask. Well, fortunately enough, we have written a separate article (Ring Seal or Solvent Weld - which soil pipe system is better?) to answer just that.

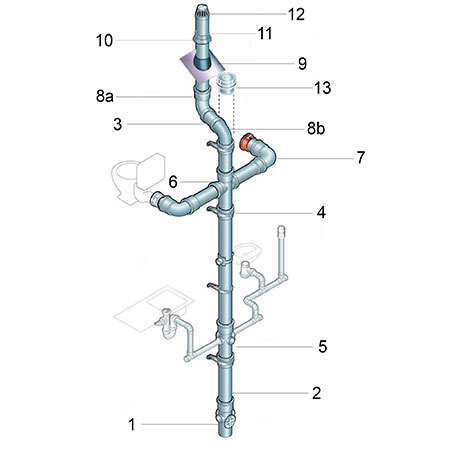

A typical 110mm PVC-U soil system will be comprised of a vertical soil stack connected to the main drain and either vented through/above the roof of the property or terminated with an air admittance valve above the highest water entry point. It will likely be made from some arrangement of the following parts:

- Access Pipe - provides an access point into the soil stack for inspection, cleaning and rodding purposes. Can also double as a connection point for waste pipes if fitted with side bosses.

- Pipe Lengths - usually available in 3m and 4m lengths, they are used to create the soil stack as well as any branching connections to the properties toilets, urinals, or bidets.

- Couplings - available either double or single socketed for connecting lengths of pipe together.

- Pipe Clips - available as pipe clips (for plain ended pipes) or socket clips (for socket ends), these fittings are used to secure the soil pipes in place against the wall and provide support around joints.

- Boss Pipes - offer connection points to allow waste pipes to join the soil stack from multiple directions.

- Branches - offer connection points to allow soil pipes from the property’s toilets, urinals, or bidets to connect to the soil stack.

- Bends - used to create a change in direction along a horizontal soil pipe run.

- Offset Bend - available in top (ring seal socket with solvent bottom) and bottom (solvent socket with a spigot bottom) pieces, they are used to create a change in direction at the top of the soil stack joined together by a short pipe length between the two solvent weld points.

- Weathering Slate - creates a weathertight seal around the soil vent pipe where it penetrates the roof to protect it from the elements.

- Weathering Collar - used to divert rainwater away from falling directly onto the weathering slate to provide extra protection.

- Vent Pipe - the length of soil pipe that penetrates up through the roof from the top of the soil stack to allow harmful gasses to escape into the atmosphere.

- Vent Terminal - fits over the exposed end of the soil vent pipe to prevent large debris, birds, and other small wildlife from entering the system.

- Air Admittance Valve - an alternative to installing a vent pipe that allows the soil stack to terminate inside the property.

Waste Pipe System Overview

A waste system, as previously mentioned, is made up of pipes and fittings designed to carry wastewater from sinks, showers, bathtubs, washing machines, and dishwashers out to the sewer. Because these pipes shouldn't have to carry any solid waste away (stop scraping leftover food down the kitchen sink!), they don't need to be as large a diameter as the soil system pipes, meaning that less space is required to install them. The most common waste pipe sizes in the UK are 32mm (suitable for low volume outlets, such as small hand basins), 40mm (suitable for most kitchen sinks, showers, and baths), and 50mm (suitable for more commercial applications, or for connecting multiple waste pipes into a single flow.

Since these pipes shouldn't be carrying contaminated water (stop peeing in the sink when the toilet is occupied!), the waste system doesn't need to be vented the way a soil system does, as no harmful gasses are produced. This only really matters, though, if your property has a waste system that runs separately to the soil system instead of connecting up to the soil stack. A combined soil and waste system will likely be vented regardless, at which point making sure you have the right-sized pipe for the right application is the primary concern. If the systems are separate, though, making sure that no contaminated water flows down your waste pipes becomes the lead concern. Again...if you are in any doubt about which type of system(s) you have, always seek the help of a professional plumber.

Traditionally, most waste pipes used to be made from either copper, iron, or lead, and many properties may still have systems that are at least partially comprised of these materials. Copper is actually still quite popular today, among some professionals, as the pipes can be made to fit into tighter spaces, are more flexible at the joints (therefore offer good resistance to vibration damage), and have a certain premium aesthetic appeal. The more modern alternative to copper waste pipes, however, is plastic. Each have their own pro's and con's, but the popularity of plastic pipes has grown exponentially due to the fact that they are much less expensive than copper pipes, easier to install, more resistant to corrosion and impact damage, and quieter at high pressure and water speeds.

Fortunately, if you have an existing system of copper piping but want to make repairs or install additional pipework using plastic pipes and fittings, many manufacturers, such as FloPlast, do have compression waste ranges that can make this happen. If you already have an existing plastic waste system, or are looking to install a new one, the biggest choice you have to make is whether to use Push-Fit or Solvent Weld connections. Again, as with the connection choices for plastic soil systems, we have put together a dedicated article, (Push-Fit or Solvent Weld - which waste pipe system is better) to properly evaluate the uses of each.

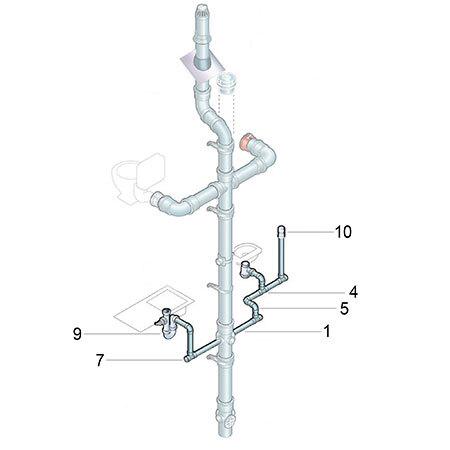

A typical plastic waste system (be it Polypropylene Push-Fit or ABS Solvent Weld) will be comprised of 32/40mm pipes and fittings connected to either:

- a 50mm pipeline that runs directly down into the drain.

- a 110mm soil stack, if the property has a combined soil and waste system.

Either way, it will likely be made from some arrangement of the following parts:

- Pipe Lengths - typically available in 3m lengths for 32mm, 40mm, and 50mm diameters.

- Couplings - used for connecting lengths of pipe together.

- Pipe Clips - used to secure the waste pipes in place and provide support around joints.

- Tees - used to connect two waste pipes (single Tee) or three waste pipes (Cross Tee) together at a 92.5-degree angle.

- Bends - used to create a change in direction along a waste pipe run.

- Conversion Bends - used to create changes in direction while also converting the connection type between push-fit and solvent weld.

- Caps - used to cap off unused outlets.

- Reducers - used to convert the diameter of the system between 32, 40, and 50mm as needed.

- Waste Traps - used under sinks, bathtubs, showers, and other wastewater appliances to create a water trap that prevents bad smells from coming back up from the drains.

- Air Admittance Valve - needed in certain long-run systems to balance the pressure in the system.

The most important parts of any soil and waste system are, arguably, its vent pipes and air admittance valves. These allow for both the safe removal of (potentially harmful) gasses and reduction of unpleasant odours, as well as, crucially, helping to regulate the pressure in the system. For this reason, let's take a closer look at these specific fittings.

Soil and Waste Vents and Valves

Whenever you flush your toilet, run a tap, or cause any water to flow within your soil and waste systems, air is always going to be carried along into the pipes. This creates a negative change in the system's pressure, which can result in a siphoning effect. As this negative pressure builds up inside the pipes, air is pulled into the system from any available opening to try and balance the pressure change. If the only available openings are your toilet, sink, and bathtub drains, the water inside the traps connected to them can be siphoned out as the air is pulled in. Should this happen, not only will it allow unpleasant odours to come back up through the drains, it can also impact the drainage ability of the system, causing loud gurgling sounds and even wastewater to come back from the trap into your sink or bathtub. Fortunately, there are two solutions to this problem:

Solving pressure build-up with a Soil Vent Pipe

The traditional way to solve this pressure issue, at least in soil systems or combined systems, is with a vent pipe installed either up through the roof (if you have an internal soil stack) or beyond the roofline (if you have an external soil stack). The term "Vent Pipe" (also known as a toilet vent pipe or drain waste vent) simply refers to the highest part of the soil system that sits above the highest wet point (i.e. the highest point where water can enter the system). The pipe itself can be just an ordinary length of soil pipe as long as its open end is protected from debris and birds entering it by a wire cage, vent terminal, or some other perforated cover.

This vent allows air to be drawn in from outside the property to rebalance the pressure in the system rather than from internal sources, thus avoiding the siphoning effect. As previously mentioned, a vent pipes other function is to allow soil system gasses to safely escape out into the atmosphere. For this reason, a vent must, according to building regulations, always terminate above the roofline of the property and be at least 900mm higher than any window or opening that is within 3 meters of the pipe.

These regulations on the height of a soil stack's termination point can result in an unsightly pipe sticking out above the level of the eaves on some properties. For external soil stacks, it also requires working at height to install, which is never advisable without the use of professional scaffolding. Internal soil stacks require a hole in the roof for the pipe to pass through that has to be fitted with a weathering slate and weathering collar to make it watertight. Also, if your property has separate soil and waste systems that don't join up until they reach the main drain, this vent pipe will not prevent pressure issues in the waste system. If your toilet system works fine, but you often get a gurgling sound from your sinks, this could be why. Should this be the case, or if you wish to avoid the problems that come with installing a soil vent pipe, the second option for solving pressure problems in soil and waste systems could be for you.

Note: If your property uses a sewage treatment plant, septic tank, or cesspool instead of a connection to the mains drains, there must be AT LEAST one open vent in the system to prevent a dangerous build-up of gasses.

Solving pressure build-up with an Air Admittance Valve

A more modern alternative solution to the pressure problem is to install an Air Admittance Valve instead of a vent pipe. Sometimes known as Durgo Valves, Air Admittance Valves (or AAV's for short) are essentially one-way valves that can be installed at the top of the soil pipe, or along a waste pipe run, to allow the free entry of air into the pipework system to balance out the pressure. The design of these valves is quite clever, as they only open when the siphoning pressure (the negative pressure caused when water flows into the pipes) builds up enough to require balancing, and only in a way that allows clean air to be drawn in without allowing foul air to escape. This is the crucial difference between the valve and the vent.

Because the Air Admittance Valve doesn't allow foul odours and harmful gasses to leave the system, it can (and in most cases should) be installed inside of the property. As long as it is installed vertically, is at least 200mm above the highest water entry point, and has plenty of space for the air to flow around it, the valve can be hidden away up in the loft or inside a cupboard. Other benefits to using Air Admittance Valves on internal soil stacks include the prevention of heat being lost through an otherwise constantly open vent, and the reduced risk of condensation building up on surfaces around the internal vent stack.

The problem with using an Air Admittance Valve instead of a Soil Vent Pipe is that by preventing the gasses from escaping through the top of the soil stack, you are causing the gasses to be forced down into the main drains and sewer system. Technically, this isn't a problem as long as there is a vent elsewhere to release them from the system, which can be located at a safe distance from the property to still comply with regulations. More often than not, though, it means that at least one house in a row of 5 on the same run must be vented to avoid dangerous build-ups. If you were planning to remove a vent pipe to replace it with an air admittance valve, you must make sure that your property isn't that 1-in-5 house before doing so.

For more information on this, as well as a more detailed look at these vents and valves, how they work, and what types are available, check out our dedicated article Soil Vent Pipes vs Air Admittance Valves.

Now that you know the difference between the two systems and how they work, and once you know which connection types will best suit your project, the next logical step on your soil and waste journey of enlightenment is to ask about how to install them.

How to install a Soil & Waste System

The age of your property and the type of soil and waste system(s) you have will largely influence your ability to DIY your way through this one. If you have an external soil stack (looks like a guttering downpipe on the outside of your property that sticks up above the roofline and has branches off it that connect to internal plumbing through the wall), this can be repaired or replaced in a fairly straightforward manner.

The caveat to this is that if you have a property with a cast iron soil stack that was built or refurbished before the year 2000, it is highly advisable to call in a professional plumber to inspect it. This is due to the potential for older systems to still contain elements of asbestos, which must be handled and disposed of very carefully.

Also, if you have a newer property with an internal soil stack, it becomes a bit more difficult. First of all, if it has a modern PVC-U system installed, you shouldn't need to replace it at all for many, many years. At most, you may need the odd repair if the system hasn't been properly maintained. Regardless, however, be it repair or replacement, any work on an internal soil stack will likely require walls to be opened up to gain access. This is a big, messy job that we would strongly recommend seeking professional help with unless your DIY skills are at an advanced level and you already know what you are doing.

Maintaining a Soil & Waste System

Properly maintaining your soil and waste systems is the best way to avoid the need to repair or replace them, and there are a few simple things you can add to your household maintenance routine to achieve this.

The primary battle you will face with these systems is in keeping them free of blockages. Blocked toilets and clogged sinks are the plumbing nightmares that most frequently haunt homeowners due to being both incredibly inconvenient to daily life and really unpleasant to clear. Preventing them from occurring in the first place is by far the best course of action to take, and really not all that difficult to do.

How to prevent blocked toilets

Excessive use of toilet paper is the biggest culprit for toilet blockages, and while few of us could adhere to a regimented piece use of one up, one down, and one to polish, there are things we should all do to better manage our usage. Being mindful of using only what is absolutely necessary, flushing the toilet several times in between paper use, and trying to avoid using the really thick, quilted toilet papers out there, are all things you can do to help prevent blockages.

Note: the vast majority of properties in the UK still use potable water to refill toilet cisterns after flushing. Therefore, to avoid wasting that precious water, multi-flushing should be reserved for only those times when paper rationing isn’t...practical, shall we say. Alternatively, why not look into getting ahead of the curve and invest in a rainwater harvesting system? You could save money and help the environment by using stored rainwater to fill your toilets and supply your household appliances. Have read of our “What is rainwater harvesting and why is it important?" article to find out more.

Above all else, though, you MUST ensure that you never try to flush anything other than toilet paper (and bodily waste, of course) down the toilet! No plastics, no nappies, no sanitary products, nor even any of those wipes that manufacturers say are "flushable", as they can all get snagged up around bends etc. and end up causing blockages. Just the toilet paper, and as little of it as possible to get the job done.

How to prevent blocked sinks

Remember how sinks are connected to waste pipes and how waste pipes are smaller in diameter than soil pipes? That means that they are even easier to block if you put the wrong things down them. Your sinks are designed to drain liquids only. Letting any kind of solid material (including bits of waste food left on your plate) wash down the plughole is like playing Russian Roulette with your waste system; the more you do it, the more likely you are to get a blockage. Even large quantities of grease and fats can get stuck around bends, solidify, and clog up the system. Basically, if it's not wastewater, don't risk putting it down your sink if you want to maintain a healthy, hassle-free waste system.

How to prevent blocked bathtubs or showers

A blocked drain in a bathtub or shower is most often caused by an accumulation of hair that provides a surface for foamy soap residue to cling to and build up into a blockage. While there are additional drain covers you can get to try and catch some of the hair, the best preventative method to avoid this kind of blockage is the regular removal of any build-ups in or around the plughole after having a bath or a shower.

How to maintain soil and waste systems for off-mains drainage

If you have a property that utilises an off-mains drainage solution (i.e. a sewage treatment plant, septic tank, or cesspool) instead of a connection to the mains sewers, operation and maintenance of your soil and waste systems become a lot more strict. If you put the wrong thing down a sink or toilet connected to the mains sewer, you might clog it up and need to call out a plumber. If you put the wrong thing down a sink or toilet connected to an off-mains drainage solution, you might cause a blockage, destroy the beneficial bacteria, compromise the storage tank, or flood your drainage field and potentially cause an environmental hazard that you, yourself, will be responsible/liable for.

Most of the things you should avoid putting down off-mains drains are fairly obvious, such as nappies, toilet wipes, motor oil, paint thinners etc. However, there are many other things that many of us wouldn't think twice about if used to being connected to the mains system, such as antibacterial cleaning agents and handwash, fats and cooking oil, and even certain washing detergents. All of these things can cause problems in sewage treatment plants and septic tanks. For more advice on this, check out the "Operation" and "Maintenance" steps in our How to install a sewage treatment plant and How to install a septic tank guides.

And there you have it - a basic guide to soil and waste systems is now yours to command...use it wisely. Once you've done all your research and found the best system for your property, the next step is to buy it and get it installed. If you decide that high-quality PVC soil and waste pipes are the way to go, we stock a great range of Floplast products to suit most installation needs.

Should you have any questions or need any further advice about your soil and waste systems, though, check out our Soil & Waste FAQ article or contact JDP today. Our team of experts are always on hand to help with all of your drainage needs.