MDPE pipes have become increasingly popular in recent years for us in various mains supply applications, but why? In this quick guide article, we aim to answer that question by giving you an overview of what MDPE pipes are, where they can be used, and the advantages they offer.

What are MDPE Pipes?

MDPE (Medium-Density Polyethylene) pipes are flexible, durable, and lightweight plastic pipes commonly used for water supply, gas distribution, and drainage. Known for their resistance to corrosion and ease of installation, MDPE pipes are a popular choice for both domestic and commercial applications due to their reliability and cost-effectiveness.

What are MDPE Pipes Used For?

MDPE pipes are incredibly versatile and can be used for a wide range of applications, such as:

- Water supply - Transporting both potable and non-potable water.

- Gas distribution - Delivering natural gas to homes and businesses.

- Drainage and sewerage - Removing wastewater from buildings and properties.

- Irrigation - Supplying water to agricultural fields.

What are the Benefits of Using MDPE Pipes?

MDPE pipes offer numerous advantages that have contributed to their widespread use in both residential and commercial settings. Some of the key benefits include:

- Durability: MDPE pipes are resistant to corrosion and impact, ensuring long-lasting performance.

- Flexibility: MDPE pipes are easier to install in tight spaces and around obstacles, reducing installation time and costs.

- Lightweight: MDPE pipes are easy to handle and transport, simplifying installation.

- Non-toxic: MDPE pipes are safe for use in potable water applications.

- Cost-effective: MDPE pipes are a more cost-efficient solution when compared to traditional materials like copper or steel.

- Environmentally friendly: MDPE pipes are recyclable and have a low environmental impact.

Why do MDPE pipes come in different colours?

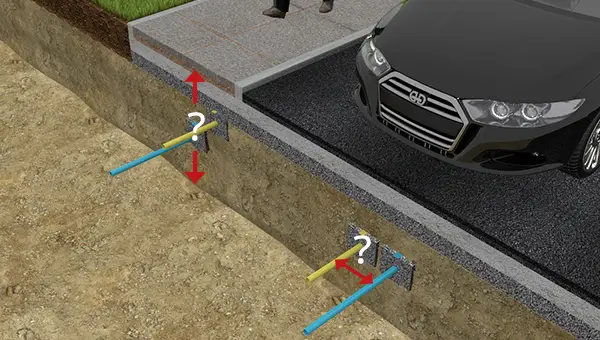

MDPE pipes are colour-coded to easily identify their intended use. This colour-coding system helps to ensure correct installation and maintenance. Here's a quick breakdown of the common colours and their uses:

- Blue MDPE: Used for underground potable (drinking) water supply.

- Black MDPE: Used for above-ground potable water supply and non-potable water applications, such as irrigation or industrial water supply.

- Yellow MDPE: Used for gas distribution.

- Blue MDPE with Brown Lines (Barrier Pipe): Designed to protect water supplies from contamination, often used in areas with poor soil conditions.

- Black MDPE with Orange Lines (Industrial Water/Sewage Pump Pipes): Used for industrial water and sewage applications that deal with higher pressures and temperatures.

For more information about the different colours of MDPE and their uses, check out our companion article The Colours and Uses of MDPE Explained

What is the difference between Blue MDPE and Black MDPE?

While both Blue and Black MDPE pipes are used for water supply systems, they are primarily used for different applications:

- Blue MDPE: Specifically designed for below-ground cold water distribution systems. These pipes are ideal for transporting potable water from the mains supply to homes and businesses.

- Black MDPE: Under BS EN 12201, plain black MDPE is used for above-ground drinking water (potable) systems – particularly in industrial and commercial settings where the pipes are exposed to the elements.

The greater difference between black and blue MDPE is in the fact that Black MDPE pipes aren’t actually made from MDPE anymore. Modern black plastic mains supply water pipes are made from HDPE (high-density polypropylene), which, under EN 13244:2003 standards, makes them suitable for a wider range of applications, such as agricultural irrigation, marine, and hydroelectric power plant water distribution systems.

What is the difference between MDPE Pipes and HDPE Pipes?

MDPE (Medium-Density Polyethylene) and HDPE (High-Density Polyethylene) are both types of polyethylene pipe, but they do have distinct characteristics:

- MDPE: More flexible, making it ideal for installations in tight spaces. It's commonly used for water supply, gas distribution, and drainage applications.

- HDPE: More rigid and has a higher pressure rating, making it suitable for high-pressure applications like water mains and industrial pipelines.

The choice between MDPE and HDPE depends on the application's specific requirements, though it is important to note that Black MDPE pipes are now typically made from HDPE already as it makes them more suitable for use above ground.

For more information on the different types of polyethylene materials, including their PE ratings and standard dimensional ratios, check out our companion article Polyethylene Pressure Pipe Materials Explained.

What is the difference between MDPE pipe and Alkathene Pipes?

Alkathene pipes and MDPE pipes are, technically, one and the same. Alkathene was a commercial name for polyethylene, which was first introduced by ICI in the 1930s and used extensively until the 1990s. Since then, while some people may still call them Alkathene, the blue and black PE pipes have become more commonly known as MDPE.

The key difference to be aware of is that the diameters of old Alkathene pipes may differ from modern MDPE. This means that if you ever need to make a connection between an old Alkathene system and a modern MDPE one, you may need to use a universal coupling adaptor that joins standard MDPE to pipes of different but similar diameters.

What are the Advantages of Using MDPE Pipes Over Other Materials?

MDPE pipes have become a popular alternative to traditional mains supply materials, such as copper, steel, or cast iron, due to their flexibility, durability, and chemical resistance.

For example:

MDPE Pipes vs Copper Pipes

MDPE pipes offer several advantages over traditional copper pipes, including:

- Flexibility: MDPE is more flexible than copper, making it easier to install in tight spaces.

- Resistance to corrosion: MDPE is not susceptible to corrosion, unlike copper, which can corrode over time, especially in acidic water.

- Lightweight: MDPE is lighter than copper, making it easier to handle and transport.

- Cost-effective: MDPE is generally more affordable than copper.

While copper pipes may offer better thermal conductivity for hot water applications, MDPE's overall performance and cost-effectiveness make it a compelling choice for many plumbing and piping projects.

Are MDPE Pipes UV Resistant?

While MDPE pipes are highly durable, prolonged exposure to direct sunlight can degrade the material over time, leading to reduced strength and flexibility. Therefore, it's crucial to protect MDPE pipes from UV radiation, especially when used in above-ground applications, or use HDPE pipes instead, which have a higher UV resistance.

Can MDPE Pipes Be Used Above Ground?

While MDPE pipes are primarily used for underground installations, they can be used above ground under certain conditions. It's important to consider factors such as exposure to UV radiation, extreme temperature fluctuations, and potential mechanical damage.

When used above ground, it's recommended to:

- Protect from UV radiation: Use UV-resistant coatings or enclosures to shield the pipes from direct sunlight.

- Consider temperature extremes: Ensure the pipe material is suitable for the specific temperature range.

- Provide adequate support: Install the pipes securely to prevent sagging or damage.

By taking these precautions, MDPE pipes can be successfully used in above-ground applications (assuming standards and restrictions allow it). However, we would recommend using HDPE pipes where possible instead due to the material being much better suited to above-ground conditions.

How Do You Join MDPE Pipes Together?

MDPE pipes can be joined together in one of three ways, depending on the pipe diameter and specific application:

- Compression Fittings: For smaller diameter pipes (up to 63mm), compression fittings are commonly used. These fittings create a secure joint by compressing a sealing ring onto the pipe.

- Electrofusion Welding: For larger diameter pipes, electrofusion welding is a reliable method. This process involves heating the ends of the pipes using a special welding machine, melting the plastic and fusing them together.

- Butt Fusion Welding: Similar to electrofusion welding, butt fusion welding involves heating the ends of the pipes and fusing them together under pressure. This method is often used for larger-diameter pipes and high-pressure applications.

It's important to follow the manufacturer's guidelines and use appropriate fittings and welding techniques to ensure a strong and durable joint.

And that’s it for this quick guide to MDPE. We hope it has been informative and helpful. If you are looking to buy quality products for your mains supply systems, we stock a great range of MDPE pipes and pressure fittings for all applications in the Mains Supply section of our online store.

If you have any other questions about MDPE pipes or mains supply systems in general, contact JDP today. Our team of experts are always on hand to help with all of your civils and drainage needs.